Productum

Intemerata chalybea fasciculus fibra vel textile nucleus interior prolixae pro textilibus calefactilibus

Product Description

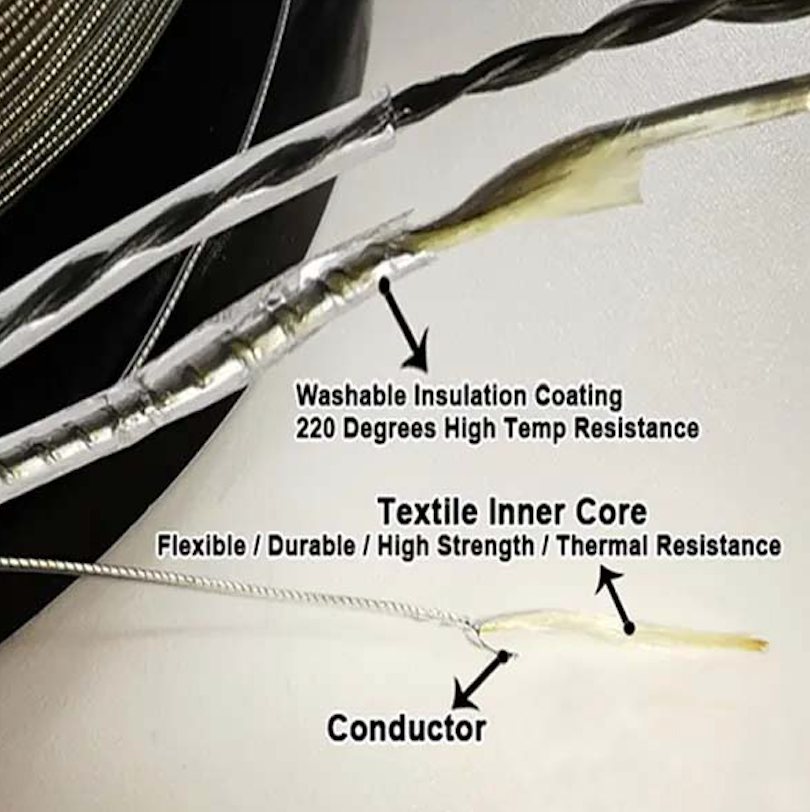

Fibra chalybs immaculata innititur fasciculo in quo diameter singulorum fibrarum 12 µ vel 14µ est. Moles fibrarum typice ab circiter 200 ad plus mille filamentis vagatur. Hoc tibi firmitatem praebet quae longe optima in genere est. Propter fibrarum fibrarum fibrarum usus, hi rudentes adhuc tenues in altiore diametro manent et sic admodum flexibiles in expediendo.

2-Plusus resistentiae inferioris extra filum et microformes cum durabilibus et flexibilibus chara- tibus tegit, speciales nostras nuclei nuclei interni textilis per metrum resistentiam declarare possunt, quibus opus est et magis flexibilitatem in consilio tibi praebet, sed tamen meliorem praebet. flex-vit, quam typi cu-ruentes. Prout in stannum exterius involutum quod fodiri potest, aes, stannum argenteum etc., possumus producere renitentes vel minus quam 1 ohm/m micro, retinacula simplicia et subductis speciebus secundum exigentiam emptoris.

Rhoncus interior nucleus micro cables commoda

Resistentia tendentes

Propter materiae structuram et compositionem, filum optimum flexionis resistentiam habet.

Flexibilitas

Funes microformes bracteolae metallicae tenuissimae adhibet ut conductor, quae super flexibilitatem cognoscit.

Ultra-Fine

Post extrusionem nostram funem microform tenuissimum ad 0.35mm esse potest.

Princeps tensile virtus

Utimur Aramid / Liquid Crystal Polymerus fibris et fibris technicis princeps sui ipsius.

Princeps Temp. Resistentia

Utimur aramid vel stanni chalybe fibrarum fasciculo fibrarum pro fibris, temp renitens a 230 gradibus ad 580 gradus ad electionem tuam.

Consummatione & coating

In mundo tuo maxime opus est ad singulas filamentorum lacquendas vel altiore extrusio super totum funem efficiens. Possumus etiam facere quod contenta extrutionis nostrae includunt FEP, PFA, PTFE, TPU etc.

INSULATION JACKET DESCRIPTIO

| Extrusio | TPE | FEP | MFA |

| Melting Point | 205° C | 255° C | 250° C |

| Continuous Opus T *temperatus | 165° C | 205° C | 225° C |

Diver Fiber fasciculos

Rhoncus interior Core Micro cable Constructiones

Ex Picta calefactio elementum

Manaticulas immaculatas chalybeas varias resistentias pererrat ad referentiam tuam.

| Diam(um). | Filamenta | Fortitudo (cN) | Pondus (g / m) | Prolongatio (%) | Conductivity (Ohm/m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257F x 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275F x 2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275F x 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275F x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F x 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275F x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90F x 2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90F x 1 | 25 | 0.110 | 1.10 |

Rhoncus interior core filum conductivum diversae resistentiae septa

| Exterior conductor | Rhoncus Intus Core | Diam mm | Conductivity ≤Ω/m |

| Aeris 0.08mm | 250D Poyester | 0.20±0.02 | 6.50 |

| Aeris 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |

| Aeris 0.05mm | 50D Kuraray | 0.10±0.02 | 12.30 |

| Aeris 0.1mm | 200D Dinima | 0.22±0.02 | 4.00 |

| Aeris 0.1mm | 250D Polyester | 1*2/0.28 | 2.00 |

| Aeris 0.1mm | 200D Kevlar | 0.22±0.02 | 4.00 |

| Aeris 0.05mm | 50D Polyester | 1*2/0.13 | 8.50 |

| Aeris 0.05mm | 70D Polyester | 0.11±0.02 | 12.50 |

| Aeris 0.55mm | 70D Polyester | 0.12±0.02 | 12.30 |

| Aeris 0.10mm | Cotton 42S/2 | 0.27±0.03 | 4.20 |

| Aeris 0.09mm | 150D Polyester | 0.19±0.02 | 5.50 |

| Aeris 0.06mm | 150D Polyester | 0.19±0.02 | 12.50 |

| Tin Copper 0.085mm | 100D Kuraray | 0.17±0.02 | 5.00 |

| Tin Copper 0.08mm | 130D Kevlar | 0.17±0.02 | 6.60 |

| Tin Copper 0.06mm | 130D Kevlar | 0.16±0.02 | 12.50 |

| Tin Copper 0.10mm | 250D Polyester | 0.23±0.02 | 4.00 |

| Tin Copper 0.06mm | 150D Polyester | 0.16±0.02 | 11.6 |

| Tin Copper 0.085mm | 200D Kevlar | 0.19±0.02 | 5.00 |

| Tin Copper 0.085mm | 150D Polyester | 0.19±0.02 | 6.00 |

| Argentum Cuprum 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |